Juicer Design Challenge

Precision Redesign and Optimization of Black and Decker Juicer for Enhanced User Experience

PART ONEPrecision CAD Replica

Disassembling and modeling every component of the juicer using calipers, without access to the original design documents or manuals. Accuracy was verified at the project's conclusion against proprietary engineering drawings, provided for educational purposes.

PART TWOUser Testing

During the testing phase, it was observed that the original model required excessive manual pressure to extract juice, leading to hand fatigue. Additionally, the pulp tended to form an even film over the drainage holes, significantly obstructing the liquid flow. Furthermore, the design of the spout posed challenges in accurately pouring juice into small to medium-sized glasses, and was inclined to cause general spillage. These findings were crucial in informing the targeted modifications to enhance user experience and efficiency.

PART THREETesting-Based Modifications

Make three modifications based on extensive product testing, to refine the juicing experience from start to cleanup, while focusing on user-friendliness and performance.

The Modifications

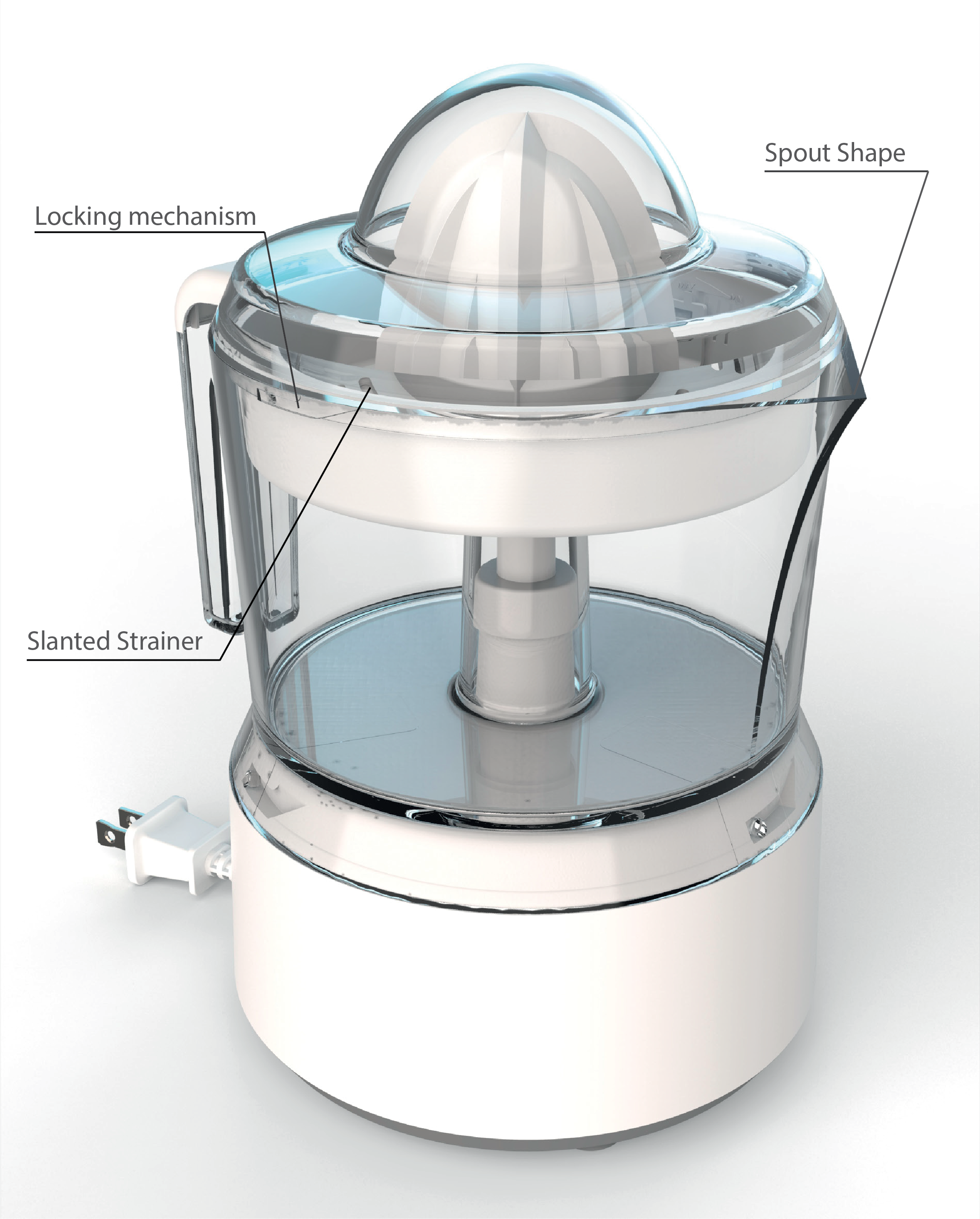

The lid was redesigned to be taller with a locking mechanism, enabling hands-free juicing that mimics the one on the lower body of the container.

The pulp strainer surface was adjusted to slope outward, ensuring juice flows directly into added gutters for better efficiency.

Lastly, the spout was refined to a narrow point, enhancing pouring precision and reducing spillage.

I was able to achieve a perfect fit without any interference by precisely measuring each component using digital calipers, and employing both solid and surfacing techniques to replicate the intricate parts of the juicer, and uniquely achieved a flawless score on both design changes and execution.